Industry News

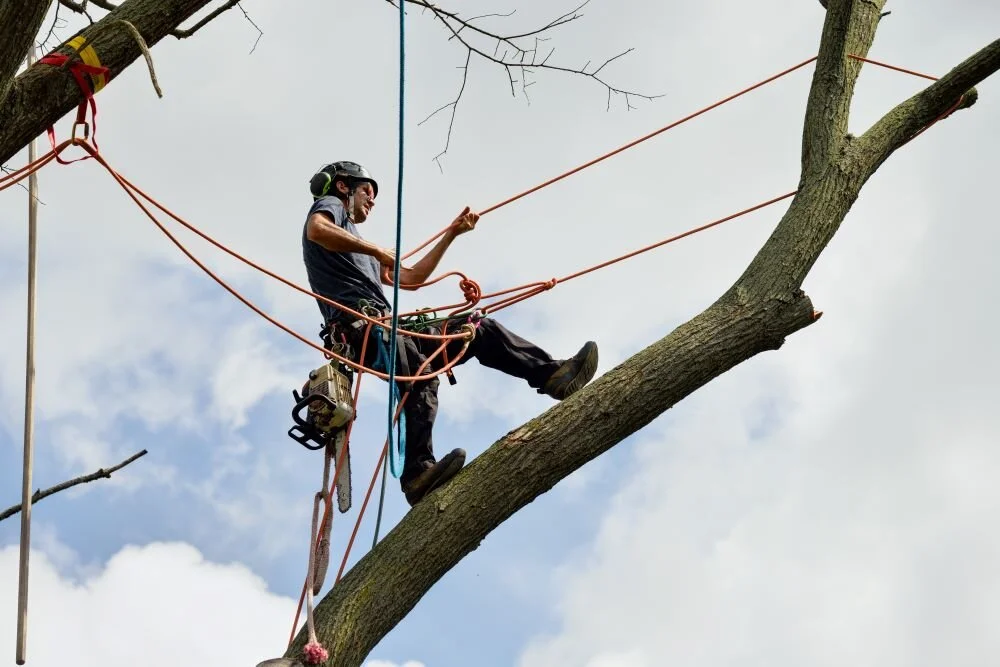

Top Five OSHA Citations the Tree Care Industry Should Avoid

Author, Rory Anderson, Account Executive, Rancho Mesa Insurance Services, Inc.

Every year, Federal OSHA conducts hundreds of inspections and issues costly citations to tree care companies. Although the Occupational Health OSHA citations can be issued for many reasons, there are five specific citations that continually plague the tree care industry every year.

Author, Rory Anderson, Account Executive, Rancho Mesa Insurance Services, Inc.

Every year, Federal OSHA conducts hundreds of inspections and issues costly citations to tree care companies. Although the Occupational Health OSHA citations can be issued for many reasons, there are five specific citations that continually plague the tree care industry every year.

1. Violation of standard 1910.132, PPE General Requirements

Employers of tree care companies can be cited for a violation if they fail to assess the workplace hazards, don’t provide personal protective equipment and fail to train employees on when and how to use it.

Average penalty: $1,300

2. Violation of standard 1910.1200, Hazard Communication

This citation is served if the employer lacks a hazard communication program for hazardous substances such as gas or hydraulic fluid periodically encountered in the tree care workplace.

Average penalty: $454

3. Violation of standard 5(a)(1), OSHA General Duty Paragraph

This is when an employer fails to provide a workplace free of recognized hazards. OSHA did not have a standard to describe the hazards specifically encountered in the tree care industry, but general duty citations usually cite passages from the ANSI Z133 standard.

Average penalty: $2,992

4.Violation of standard 1910.67, Vehicle-mounted Elevating and Rotating Work Platforms (e.g., bucket trucks and aerial lifts).

This citation can be issued if the employer fails to provide fall protection for the lift operator or fails to properly inspect the lift.

Average penalty: $3,325

5. Violation of standard 1910.135, Head Protection

This citation occurs when the employer fails to ensure that employees wear hard hats when required.

Average penalty: $1,262

As a tree care company, it is important that employee trainings routinely cover these five topics. While the standard safety training topics for the tree care industry are impactful (e.g., fall protection, chainsaw safety, etc.) and vital to your company’s safety success, these top five OSHA citations should be considered a high priority for regular review.

Access these specific trainings from our Risk Management Center library. If you’re not a Rancho Mesa client, please contact me at (619) 486-6437 or randerson@ranchomesa.com for a free Risk Management Center trial.

Implementing an Effective Fall Safety Program Can Have Serious Impacts

Author, Casey Craig, Account Executive, Rancho Mesa Insurance Services, Inc.

Year after year, falls are among the leading type of workers’ compensation claims and generate the highest claim costs. They account for multiple infractions on the top 10 most frequently cited standards, according to the Occupational Safety and Health Administration. How can you, as a business owner, control your exposure and keep your employees productive and healthy?

Author, Casey Craig, Account Executive, Rancho Mesa Insurance Services, Inc.

Year after year, falls are among the leading type of workers’ compensation claims and generate the highest claim costs. They account for multiple infractions on the top 10 most frequently cited standards, according to the Occupational Safety and Health Administration. How can you, as a business owner, control your exposure and keep your employees productive and healthy?

Prevention

According to the Centers for Disease Control, “27% of the 900,380 nonfatal work injuries resulting in days away from work in 2018 were related to slips, trips, and falls.” That’s a shockingly large number especially when 100% of falls are preventable if you take the time to plan, according to the National Safety Council (NSC). The NSC recommends:

Walking a job before employees get there to ensure proper set up is achievable with the equipment you are bringing for that job.

Pay attention to environmental conditions such as wind, rain, or excessive heat.

Check your equipment frequently to ensure nothing is worn down or damaged.

Make sure employees are wearing the proper foot wear and other Personal Protective Equipment (PPE) items required for the individual job needs.

Having employees working on ladders or scaffolding is essential for some jobs, and fortunately is a risk you can control. In addition to evaluating the work site, the equipment, the environmental factors, and PPE needed, you should also evaluate the health and fitness of all employees. Factors to consider should include the employee’s:

Experience

Fitness level

Age

Height Matters

A fatal fall can happen at almost any height. According to the NSC, only 16% of fatal falls in 2016 occurred as a result of a fall from over 30 feet; however, 53% of fatal falls that year resulted from below 20 feet. Given this data, best practices would dictate that construction companies should step back and reevaluate the safety procedures they have in place and determine if any changes need to be made, particularly for jobs that are considered the lower heights.

RM365 Advantage Safety Star™ Program

To get your employees properly trained, we recommend enrolling in our RM365 Advantage Safety Star™ program that includes Fall Prevention training. This program includes fundamental safety topics that allows your foreman or key management team to go through internet-based safety trainings and earn their Safety Star certification. This program has shown to improve safety while helping to reduce your workers’ compensation premiums. Register to start your RM365 Advantage Safety Star™ program, today.

Rancho Mesa understands the exposure our clients face on a daily basis and can help implement safety procedures to mitigate these risks. Underestimating a project’s risk or undertraining employees is an exposure you can address.

If you would like help in reviewing your safety protocols and procedures or if you have further questions, do not hesitate to reach out to me at (619) 438-6900 or email me at ccraig@ranchomesa.com.

OSHA Announces Top 10 Cited Violations for FY 2017

Author, Sam Clayton, Vice President, Construction Group, Rancho Mesa Insurance Services, Inc.

The Occupational Safety and Health Administration (OSHA) released its preliminary top 10 citation list for fiscal year 2017 at the annual National Safety Council (NSC) Congress and Expo, held in late September 2017.

Author, Sam Clayton, Vice President, Construction Group, Rancho Mesa Insurance Services, Inc.

The Occupational Safety and Health Administration (OSHA) released its preliminary top 10 citation list for fiscal year 2017 at the annual National Safety Council (NSC) Congress and Expo, held in late September 2017.

“One thing I’ve said before in the past on this is, this list doesn’t change too much from year to year,” said Patrick Kapust, deputy director of OSHA’s Directorate of Enforcement and Programs, during the expo presentation. “These things are readily fixable. I encourage folks to use this list and look at your own workplace.”

OSHA compiled the list using data collected from incidents occurring from October 2016 through September 2017.

- Fall Protection in Construction: 6,072 violations.

Frequently violated requirements include unprotected edges and open sides in residential construction and failure to provide fall protection on low-slope roofs - Hazard Communication: 4,176 violations.

Not having a hazard communication program topped the violations, followed by not having or providing access to safety data sheets - Scaffolding: 3,288 violations.

Frequent violations include improper access to surfaces and lack of guardrails - Respiratory Protection: 3,097 violations.

Failure to establish a respiratory protections program topped these violations, followed by failure to provide medical evaluations - Lockout/Tagout: 2,877 violations.

Frequent violations were inadequate worker training and inspections not completed. - Ladders in Construction: 2,241 violations.

Frequent violations include improper use of ladders, damaged ladders and using the top step. - Powered Industrial Trucks: 2,162 violations.

Violations include inadequate worker training and refresher training. - Machine Guarding: 1,933 violations.

Exposure points of operation topped these violations. - Fall Protection-training requirements: 1,523 violations.

Common violations include failure to train workers in identifying fall hazards and proper use of fall protection equipment. - Electrical-wiring methods: 1,405 violations.

Violations of this standard were found in most general industry sectors, including food and beverage, retail and manufacturing

Training materials for each of the items on the OSHA list are available within the Risk Management Center. Contact Rancho Mesa Insurance Services, Inc. at (619) 937-0164, for more information.